1 . FLUID MECHANICS AND HYDRAULIC MACHINES LAB

Equipment List

| # | Equipment Name |

|---|---|

| 1.1 | Combined Major and Minor Loss Apparatus |

| 1.2 | Metacentric Height Apparatus |

| 1.3 | Orifice and Mouth Piece Apparatus |

| 1.4 | Combined Venturimeter and Orifice Meter Apparatus |

| 1.5 | Rectangular and Triangular Notch Apparatus |

| 1.6 | Water Meter and Rotameter Test Rig |

| 1.7 | Bernoulli’s Theorem Apparatus |

| 1.8 | Pelton Wheel Turbine |

| 1.9 | Kaplan Turbine |

| 1.10 | Francis Turbine |

| 1.11 | Centrifugal Pump |

| 1.12 | Reciprocating Pump |

| 1.13 | Gear Pump Test Rig |

| 1.14 | Dead Weight Pressure Gauge Tester |

| 1.15 | Reynolds Apparatus |

| 1.16 | Jet on Vanes Apparatus |

2 . MACHINE TOOLS LAB-I

Equipment List

| # | Equipment Name |

|---|---|

| 2.1 | CNC Lathe |

| 2.2 | All Geared Centre Lathe |

| 2.3 | Shaping Machine |

| 2.4 | Milling Machine |

| 2.5 | Slotting Machine |

| 2.6 | Surface Grinding Machine |

| 2.7 | Cylindrical Grinding Machine |

| 2.8 | Tool and Cutter Grinding Machine |

| 2.9 | Radial Drilling Machine |

| 2.10 | Upright Drilling Machine |

3 . MACHINE TOOL LABS II

Equipment List

| # | Equipment Name |

|---|---|

| 3.1 | Autocollimator |

| 3.2 | Strain Measurement |

| 3.3 | Tool Makers Microscope |

| 3.4 | Profile Projector |

| 3.5 | Sine Bar |

| 3.6 | Thermocouple |

| 3.7 | Optical Flat and Monochromatic Light Unit |

| 3.8 | Stroboscope |

| 3.9 | Load Cell Trainer |

| 3.10 | Vibration Measuring Apparatus |

| 3.11 | Dead Weight Pressure Gauge Tester |

| 3.12 | Analog and Digital Dial Gauge |

| 3.13 | Vernier Caliper |

| 3.14 | Micrometre |

| 3.15 | Gear Tooth Vernier Caliper |

| 3.16 | LVDT |

| 3.17 | Slip Gauges |

| 3.18 | Bevel Protractor |

| 3.19 | Surface Plate |

| 3.20 | Metallurgical Microscope |

| 3.21 | Double Disc Polishing Machine |

| 3.22 | Vernier Height Gauge |

| 3.23 | Bench Center |

| 3.24 | Digital Vernier Caliper |

| 3.25 | Inside Micrometre |

| 3.26 | Metal Samples |

4 . COMPOSITE LAB

Equipment List

| # | Equipment Name |

|---|---|

| 4.1 | Kemi Hot Air Oven |

| 4.2 | Remi -Magnetic Stirrer with Hot Plate |

| 4.3 | Digital Ultrasonic Cleaner |

| 4.4 | Vacuum Pump with Desiccator |

| 4.5 | Infra Digital Balance – 1 Mg Accuracy |

5 . THERMAL ENGINEERING LAB-I

Equipment List

| # | Equipment Name |

|---|---|

| 5.1 | Single Cylinder Four Stroke Petrol Engine |

| 5.2 | Four Cylinder Four Stroke Petrol Engine |

| 5.3 | Single Cylinder Four Stroke Diesel Engine |

| 5.4 | Twin Cylinder Four Stroke Diesel Engine |

| 5.5 | Two Stage Reciprocating Air Compressor |

| 5.6 | Centrifugal Air Blower |

| 5.7 | Flash and Fire Point Tester |

| 5.8 | Redwood Viscometer |

| 5.9 | Valve Timing Arrangement |

| 5.10 | Cut Section Model For 2 Stroke And 4 Stroke Engines |

| 5.11 | Orsat Gas Analysis |

| 5.12 | Automobile Parts |

6 . THERMAL ENGINEERING LAB- II

Equipment List

| # | Equipment Name |

|---|---|

| 6.1 | Heat Pipe Apparatus |

| 6.2 | Parallel - Counter Flow Heat Exchanger Apparatus |

| 6.3 | Natural Convection Apparatus |

| 6.4 | Air Conditioning Apparatus |

| 6.5 | Vapour Compression Refrigeration Test Rig |

| 6.6 | Insulating Powder Apparatus |

| 6.7 | Composite Wall Apparatus |

| 6.8 | Emissivity Measurement Apparatus |

| 6.9 | Stefan Boltzmann Apparatus |

| 6.10 | Dead Weight Pressure Gauge |

| 6.11 | Drop Wise and Film Wise Condensation Apparatus |

| 6.12 | Thermal Conductivity of Liquids |

| 6.13 | Forced Convection Apparatus |

7 . COMPUTER AIDED DESIGN AND ANALYSIS LAB

8 . MECHANICAL ENGINEERING LAB

Equipment List

| # | Equipment Name |

|---|---|

| 8.1 | Centrifugal Governor |

| 8.2 | Motorised Gyroscope |

| 8.3 | Whirling of Shaft Apparatus |

| 8.4 | Pneumatic Trainer Kit |

| 8.5 | Hydraulic Trainer Kit |

| 8.6 | PC Based Data Acquisition System |

| 8.7 | Free and Forced Vibration Setup |

| 8.8 | 3D Printer |

9 . ENGINEERING WORKSHOP

Equipment List

| # | Equipment Name |

|---|---|

| 9.1 | Fitting Section |

| 9.2 | Smithy Section |

| 9.3 | Sheet Metal Section |

| 9.4 | Foundry Section |

| 9.5 | Welding Section |

10 . PROJECT LABORATORY

Equipment List

| # | Equipment Name |

|---|---|

| 10.1 | Shuchitwa |

| 10.2 | Flood Emergency Rescue Robot |

| 10.3 | Containment Zone Tracking and Temperature Detection System (CTDS) |

| 10.4 | Oxy Mobile: Portable Oxygen Extractor |

| 10.5 | Parabolic Solar Water Heater |

| 10.6 | Shore Guard: Autonomous Beach Cleaning Robot |

| 10.7 | Manual Adhesion Tester Machine |

11 . MECHANICAL DEPARTMENT LIBRARY

12 . CLASSROOMS

1.1

Combined Major and Minor Loss Apparatus

1.3

Orifice and Mouth Piece Apparatus

1.4

Combined Venturimeter and Orifice Meter Apparatus

1.5

Rectangular and Triangular Notch Apparatus

1.6

Water Meter and Rotameter Test Rig

1.7

Bernoulli’s Theorem Apparatus

1.8

Pelton Wheel Turbine

1.9

Kaplan Turbine

1.10

Francis Turbine

1.11

Centrifugal Pump

1.12

Reciprocating Pump

1.13

Gear Pump Test Rig

1.14

Dead Weight Pressure Gauge Tester

1.15

Reynolds Apparatus

1.16

Jet on Vanes Apparatus

2.1

CNC Lathe

2.2

All Geared Centre Lathe

2.3

Shaping Machine

2.4

Milling Machine

2.5

Slotting Machine

2.6

Surface Grinding Machine

2.7

Cylindrical Grinding Machine

2.9

Radial Drilling Machine

2.10

Upright Drilling Machine

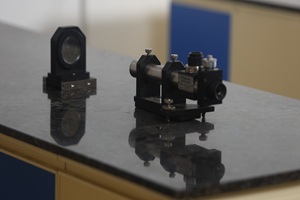

3.1

Autocollimator

3.2

Strain Measurement

3.3

Tool Makers Microscope

3.4

Profile Projector

3.5

Sine Bar

3.6

Thermocouple

3.7

Optical Flat and Monochromatic Light Unit

3.8

Stroboscope

3.10

Vibration Measuring Apparatus

3.11

Dead Weight Pressure Gauge Tester

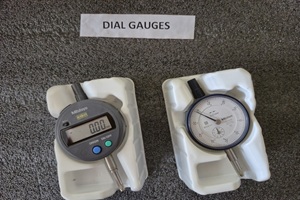

3.12

Analog and Digital Dial Gauge

3.13

Vernier Caliper

3.14

Micrometre

3.15

Gear Tooth Vernier Caliper

3.16

LVDT

3.17

Slip Gauges

3.19

Surface Plate

3.20

Metallurgical Microscope

3.21

Double Disc Polishing Machine

3.22

Vernier Height Gauge

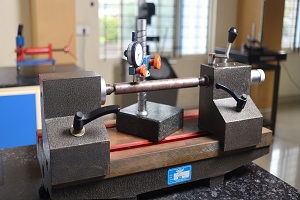

3.23

Bench Center

3.24

Digital Vernier Caliper

3.25

Inside Micrometre

3.26

Metal Samples

4.1

Kemi Hot Air Oven

4.2

Remi -Magnetic Stirrer with Hot Plate

4.3

Digital Ultrasonic Cleaner

4.4

Vacuum Pump with Desiccator

5.1

Single Cylinder Four Stroke Petrol Engine

5.2

Four Cylinder Four Stroke Petrol Engine

5.3

Single Cylinder Four Stroke Diesel Engine

5.4

Twin Cylinder Four Stroke Diesel Engine

5.5

Two Stage Reciprocating Air Compressor

5.6

Centrifugal Air Blower

5.9

Valve Timing Arrangement

5.10

Cut Section Model For 2 Stroke And 4 Stroke Engines

5.12

Automobile Parts

6.1

Heat Pipe Apparatus

6.2

Parallel - Counter Flow Heat Exchanger Apparatus

6.3

Natural Convection Apparatus

6.4

Air Conditioning Apparatus

6.5

Vapour Compression Refrigeration Test Rig

6.6

Insulating Powder Apparatus

6.7

Composite Wall Apparatus

6.8

Emissivity Measurement Apparatus

6.9

Stefan Boltzmann Apparatus

6.11

Drop Wise and Film Wise Condensation Apparatus

6.12

Thermal Conductivity of Liquids

6.13

Forced Convection Apparatus

8.1

Centrifugal Governor

8.2

Motorised Gyroscope

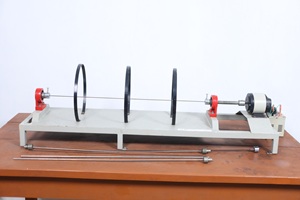

8.3

Whirling of Shaft Apparatus

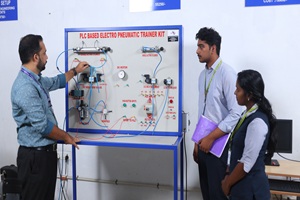

8.4

Pneumatic Trainer Kit

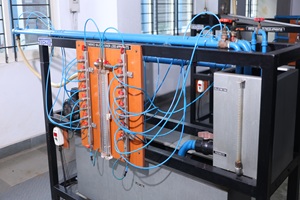

8.5

Hydraulic Trainer Kit

8.7

Free and Forced Vibration Setup

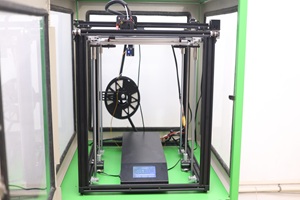

8.8

3D Printer

9.1

Fitting Section

9.2

Smithy Section

10.1

Shuchitwa

10.3

Containment Zone Tracking and Temperature Detection System (CTDS)